Source – X.com

The significance of F1 upgrades has brought attention to wind tunnel performance.

In the high-octane world of Formula 1, where fractions of a second can mean the difference between victory and defeat, the quest for the ultimate racing advantage is relentless. This season, as the battle for supremacy intensifies, a surprising yet compelling theory has emerged: the key to success may lie in the state-of-the-art wind tunnels that teams utilize. McLaren’s performance in 2024, particularly with its MCL38, underscores this idea, revealing a fascinating story of technological advancement and competitive strategy.

McLaren’s impressive success amidst the turbulent F1 season, where Ferrari, Red Bull, Aston Martin, and Mercedes have stumbled with various development issues, raises a pivotal question: why has McLaren been so successful in refining its car while others falter? The answer, it appears, might be tied to one significant factor—the wind tunnel.

The Wind Tunnel Factor

Source – Autosport

The correlation between McLaren’s upturn in performance and its investment in the latest generation wind tunnel is no mere coincidence. As paddock insiders speculate, the advanced wind tunnel at McLaren’s Woking base has played a crucial role in the team’s ability to optimize the MCL38 with precision.

Contrast this with the situation at Red Bull, where the team is grappling with problems linked to its Bedford wind tunnel—a facility modernized from its Cold War-era origins. Christian Horner, Red Bull’s boss, inadvertently highlighted the issue after the Italian Grand Prix, revealing that the disconnect between the car’s front and rear, which the wind tunnel data fails to capture, is being exposed on the track. This discrepancy highlights how critical accurate wind tunnel data is for effective car development. When a wind tunnel provides flawed data, it becomes a formidable challenge for teams to discern whether new parts are improving performance or not.

The Evolution of Wind Tunnel Technology

Source – Motorsport Engineer

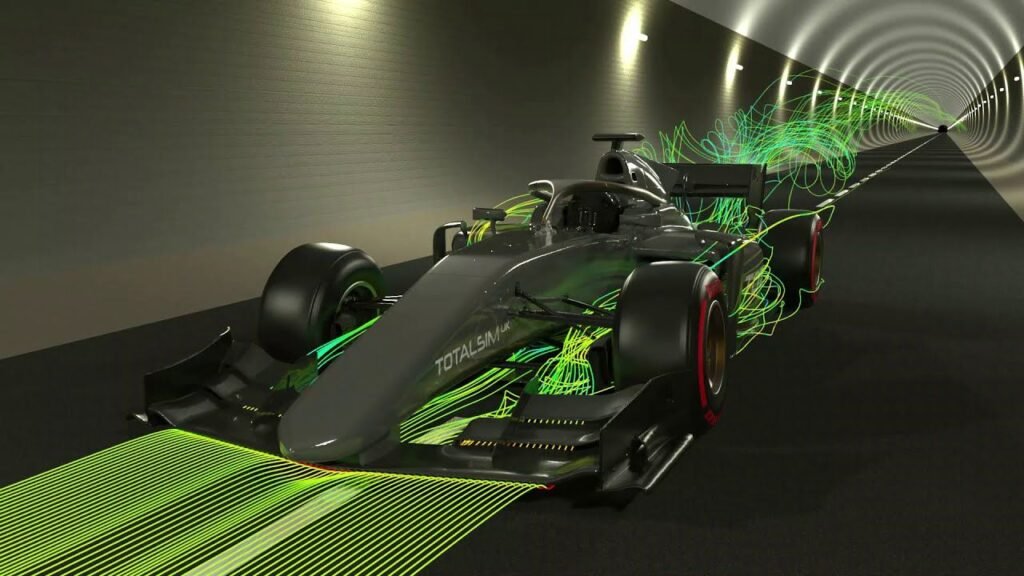

Wind tunnel technology has evolved significantly, and the differences between current facilities are profound. Modern wind tunnels are equipped with advanced features to provide more accurate simulations of real-world conditions. For instance, the ground-effect cars of today are extremely sensitive to ride height and under-floor aerodynamics, making precision in data critical.

Ferrari’s recent decision to shut down its wind tunnel for a mid-season refurbishment illustrates the importance of staying ahead in this technological race. The upgrade focused on improving yaw angle simulation to better replicate airflow as the car navigates corners. Ferrari also revamped its rolling floor—a critical component for simulating the track surface more realistically. Unlike the traditional smooth metal surfaces, the new rolling floors use rubber-type materials that better mimic the disruptions of real-world asphalt, essential for accurate aerodynamic testing.

The complexity of ground-effect cars, which rely heavily on the underfloor airflow, demands a rolling floor that can replicate various track conditions. Teams now use different types of rough surfaces to simulate the diverse array of circuits on the F1 calendar, from the bumpy terrain of Bahrain to the smoothness of Montreal. Some teams have even explored 3D printing rolling road track surfaces to match specific tracks’ unique characteristics.

Advanced Sensors and Data Accuracy

Source – Trimech Enterprise Solutions

The integration of advanced sensors is another game-changer. Aston Martin’s engineering director, Luca Furbatto, pointed out that modern wind tunnels benefit from cutting-edge flow visualization tools that were not available two decades ago. These sensors allow for detailed scanning of airflow across different parts of the car, offering more precise feedback and improving the quality of the data collected.

McLaren’s latest wind tunnel is a testament to this technological leap. While the exact details of its advanced features remain closely guarded, the impact of such a facility on McLaren’s track performance is evident. The team’s aerodynamic engineers, armed with state-of-the-art tools, have successfully translated wind tunnel data into on-track success, underscoring the significance of both technology and human expertise.

The Human Element in Aerodynamics

Despite the impressive advancements in wind tunnel technology, Andrea Stella, McLaren’s team principal, emphasizes that no tool operates in isolation. The wind tunnel is a powerful asset, but its effectiveness depends on how well the aerodynamic team utilizes the data it provides. Stella credits McLaren’s success not just to the new wind tunnel but to the expertise and dedication of the team that interprets and applies the data to achieve a competitive edge.

As the season progresses, the emphasis on technological prowess and human skill will continue to shape the outcomes. McLaren’s story highlights a crucial lesson in Formula 1: while having the latest equipment is vital, the true measure of success lies in how effectively teams leverage their resources to drive performance on the track.

In this era of intense competition, where every detail counts, the wind tunnel wars are a testament to the relentless pursuit of perfection in Formula 1. McLaren’s current advantage serves as a reminder of the crucial role that cutting-edge technology and skilled human interpretation play in the ever-evolving landscape of Formula 1 racing.